Samvid is one of the closely held companies that was incorporated in 2011 and involved in several activities associated with the mechanical and piping design. We are serving in the industry for a decade with tons of experience in the area. We work in major independent Plant Engineering inclusive of Piping & Equipment designing for the world-class standard and fulfilling the needs of the clients. We do enough research and understand customer needs. With a clear understanding, we move to the plant designing process to produce the expected results.

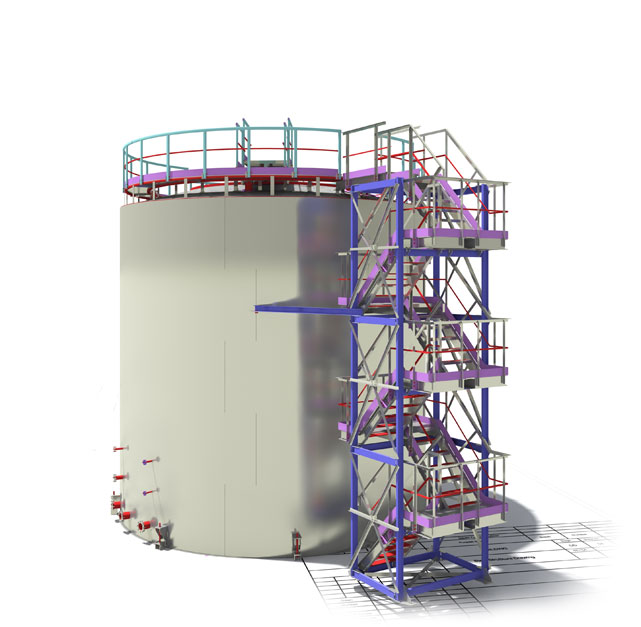

Our process design engineering service enables our customers to optimize the capital expenditure and enhance the operational efficiency downstream towards the process. We are capable enough to offer end to end solutions to have the right match concerning the different engineering solutions like Piping Design, 3D Modelling, stress analysis, Pressure Vessels design including heat exchangers, Tank designs and other equipment design.

Our innovation is one of the kinds of business models that make the most compatible designing partner for the companies of all sizes belonging to various industries. We work with the technical outcome along with the standards to plant engineering. With a decade of the journey, we have worked with different partners, and this made us establish our presence in various industries as the Plant engineering services.

We support all sorts of process equipment design and analysis projects from the pressure vessel design and fabrication drawing, and sometimes. When a client approaches us, we get to know their requirements and the nature of the industry. We analyze the things and trends associated with the industry to design the equipment accordingly. With this information, we start working with the design and bring out the most suitable design with optimum size shape and all other parameters. We use so many technological tools and the results of the rising technology to bring the most suitable solution. All our designs are tailor made for client’s requirement as well as optimum in cost and effort.